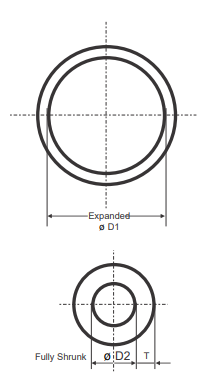

| CODE | As Supplied | After Recovered | App. bus-bar | Standard length | |

|---|---|---|---|---|---|

| ø D1 (max.) | ø D2 (max.) | T (min.) | dim. (mm.) | (m/spool) | |

| DBM - 36/10 | 25 | 10 | 2.0 | 25*3 | 30 |

| DBM - 30/12 | 30 | 12 | 2.0 | 35*4 | 30 |

| DBM - 35/14 | 35 | 14 | 2.0 | 35*4 | 30 |

| DBM - 40/16 | 40 | 16 | 2.0 | 40*5 | 30 |

| DBM - 50/20 | 50 | 20 | 2.0 | 50*5 | 15 |

| DBM - 65/25 | 65 | 25 | 2.0 | 65*8 | 15 |

| DBM - 75/30 | 75 | 30 | 2.0 | 75*8 | 15 |

| DBM - 100/40 | 100 | 40 | 2.0 | 100*10 | 15 |

| CODE | As Supplied | After Recovered | App. bus-bar | Standard length | |

|---|---|---|---|---|---|

| ø D1 (max.) | ø D2 (max.) | T (min.) | dim. (mm.) | (m/spool) | |

| DBT - 15/6 | 15 | 6 | 3.0 | 15*3 | 15 |

| DBT - 25/10 | 25 | 10 | 3.0 | 25*4 | 15 |

| DBT - 30/12 | 30 | 12 | 3.0 | 35*4 | 15 |

| DBT - 40/16 | 40 | 16 | 3.0 | 40*5 | 15 |

| DBT - 50/20 | 50 | 20 | 3.0 | 50*5 | 15 |

| DBT - 65/25 | 65 | 25 | 3.0 | 65*8 | 15 |

| DBT - 75/30 | 75 | 30 | 3.0 | 75*8 | 15 |

| DBT - 85/35 | 85 | 35 | 3.0 | 85*10 | 15 |

| DBT - 100/40 | 100 | 40 | 3.0 | 100*10 | 15 |

| DBT - 120/50 | 120 | 50 | 3.0 | 120*12 | 1000 mm |

| DBT - 150/60 | 150 | 60 | 3.0 | 150*15 | 1000 mm |

| Property | Typical Data | Test Method |

|---|---|---|

| Tensile Strength | 10 N / mm2 | ASTM D 2671 |

| Longitudinal shrinkage | 0 to – 10% | ASTM D 2671 |

| Elongation at break | 200% | ASTM D 2671 |

| Elongation at break after aging | > 500% | ASTM D 2671 / 120℃, 168 hrs. |

| Dielectric strength | > 10 kV / mm | IEC 243 / ENATS 0913 |

| Dielectric constant | Max. 3.0 | IEC 250 |

| Volume resistance | 1012Ω cm. | IEC 93 |

| Flammability (Oxygen index) | > 25 | ASTM 4589 |

| Copper corrosion | 120℃, 168 hrs., no corrosion | ASTM D 2671 |

| Cold bending | -40℃, 4 hrs., no cracking | ASTM D 2671 |

| Water absorption | < 0.5% | ISO 62 / 23℃, 14 days. |

Kindly provide your information, and our expert team will get in touch with you shortly.