Heat shrinkable power cable jointing kits are specialized sets of materials designed to join two or more sections of power cables while preserving the electrical, mechanical, and environmental integrity of the cable system. The core technology involves polymeric tubing that shrinks tightly around the cable components when exposed to heat, forming a strong, moisture-resistant, and insulating barrier.

These kits are widely used in low, medium, and high-voltage applications, particularly for XLPE, PVC, PILC, and EPR-insulated cables.

Key Components of Heat Shrinkable Cable Jointing Kits

A typical heat shrinkable jointing kit contains:

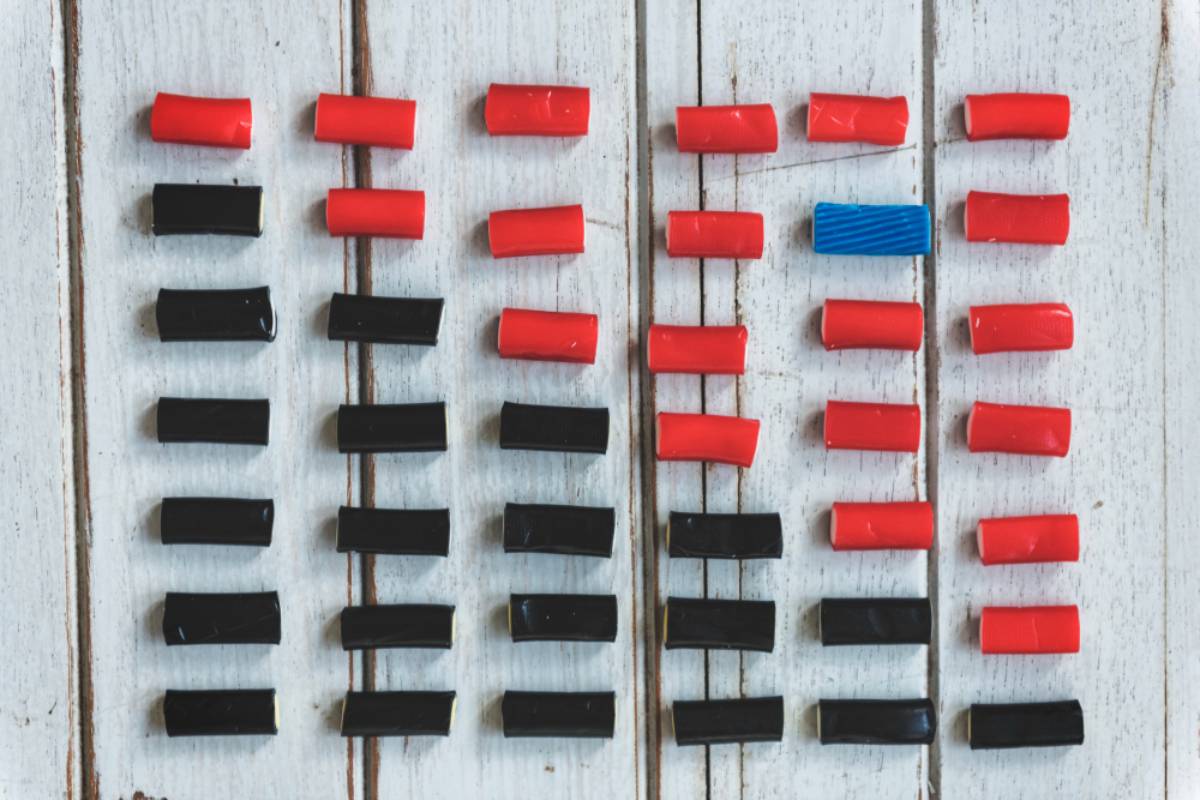

- Heat Shrink Tubes: These are pre-expanded polymer sleeves that shrink on heating to form a tight and protective seal around the joint.

- Stress Control Tubes or Mastic: Used in medium/high-voltage applications to reduce electrical stress at the insulation interface.

- Insulating Tubes: Provide electrical insulation over the cable joint.

- Conductive Paint or Tapes: Helps in the even distribution of electric field stresses.

- Adhesive-lined Sleeves or Mastics: Provide waterproofing and environmental sealing.

- Metallic Shielding: Often includes copper mesh or braid to recreate the electromagnetic shielding lost at the joint.

- Mechanical Connectors or Compression Ferrules: Ensure proper electrical continuity.

- Earth Continuity Kits: For maintaining the continuity of metallic screens or armor.

Types of Heat Shrink Cable Jointing Kits

Based on voltage level and application, heat shrinkable jointing kits can be broadly classified into:

1. Low Voltage (LV) Jointing Kits (up to 1.1kV)

- Commonly used in industrial, commercial, and residential power supply applications.

- Provide basic insulation and environmental protection.

2. Medium Voltage (MV) Jointing Kits (3.3kV to 33kV)

- Used in substations, utilities, renewable energy installations, and industrial plants.

- Include advanced components like stress control materials and dual-layer insulation tubes.

3. High Voltage (HV) Jointing Kits (above 33kV)

- Designed for critical infrastructure and transmission lines.

- Rigorously tested for dielectric strength, impulse withstand voltage, and thermal endurance.

Advantages of Heat Shrinkable Cable Jointing Kits

- High Reliability

The heat shrink process forms a uniform, void-free insulation that adheres tightly to the cable surface, minimizing the risk of partial discharge or moisture ingress.

- Excellent Electrical Insulation

Made from high dielectric strength materials, these kits ensure safe and reliable electrical performance even under harsh load conditions.

- Moisture and Environmental Protection

Heat shrink tubes are inherently water-resistant and UV-stabilized, offering excellent protection in underground, outdoor, and marine installations.

- Wide Range Compatibility

Can be used for various cable types — single core or three-core, armored or unarmored, and PILC or XLPE insulated cables.

- Ease of Transportation and Storage

Compact and lightweight compared to resin or cast-type joints. No heavy equipment or curing time is needed.

- Time-Efficient Installation

Installation is faster compared to traditional cast resin joints. Minimal downtime for power systems during maintenance or extension.

Installation Process

Installing heat shrinkable cable jointing kits should be done by trained professionals, following manufacturer-specific guidelines. The general steps include:

- Preparation: Cut the cable ends and strip insulation, bedding, and armoring as per jointing instruction.

- Connector Installation: Crimp or mechanically fix the conductor connectors between cable ends.

- Stress Control Application: Apply stress control components to manage electrical field concentrations.

- Insulation & Shielding: Sequentially apply insulation and conductive layers, using a gas torch to heat-shrink each sleeve.

- Sealing: Apply adhesive-lined sealing sleeves or mastics to prevent moisture ingress.

- Grounding & Final Checks: Install grounding braids and test for continuity and insulation resistance.

Common Applications

Heat shrinkable power cable jointing kits are indispensable in the following sectors:

- Utilities and Power Distribution Companies

For underground cable networks and feeder lines. - Renewable Energy Projects

In solar parks and wind farms to connect multiple segments of power transmission lines. - Industrial Facilities

For maintaining continuous power supply in high-load environments such as oil & gas, steel, cement, and manufacturing industries. - Infrastructure Projects

Used in airports, railways, metro systems, and urban development projects. - Telecommunication and Data Centers

Ensure stable and uninterrupted power connections for critical operations.

Quality and Compliance Standards

To ensure safety, durability, and optimal performance, heat shrinkable cable jointing kits must comply with various international standards, including:

- IEC 60502-4 – for power cables with extruded insulation

- IEEE 404 – for medium-voltage cable joints

- EN 50393 – performance requirements for cable accessories

- IS 13573 – Indian standard for heat shrinkable accessories

Certified kits undergo testing for impulse voltage, thermal cycling, partial discharge, water penetration, and mechanical impact resistance.

Maintenance and Inspection Tips

Even though these joints are designed for long-term performance, periodic inspection ensures system reliability:

- Visual Checks: Look for signs of overheating, cracking, or moisture.

- Thermal Imaging: Helps detect hotspots that could indicate poor joints or loose connectors.

- Insulation Resistance Testing: Ensures continued dielectric integrity over time.

Key Takeaway

As power infrastructure continues to evolve and expand, heat shrinkable cable jointing kits remain a critical component in ensuring the reliability, safety, and efficiency of electrical systems. Their proven durability, strong insulating properties, and adaptability to various environments make them ideal for a wide range of applications — from underground utility lines to industrial facilities and renewable energy projects.

Proper installation and regular inspection are essential to maintain the performance of these joints. Selecting kits that meet international standards and suit specific voltage and cable types helps minimize operational risk and extend the service life of electrical networks. Understanding the function and selection criteria of heat shrinkable jointing kits is essential for engineers, contractors, and project managers aiming to build robust, future-ready power systems.