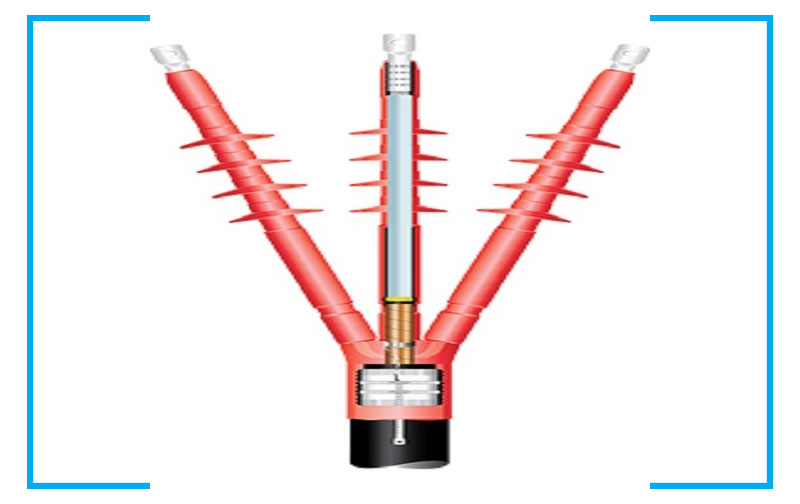

In electrical engineering, heat shrinkable cable termination is a crucial step that guarantees a safe and dependable connection between cables. Using this method, cable joints and terminations are provided with insulation, environmental protection, and mechanical strength. We will delve into the nuances of heat shrinkable cable termination in this guide, looking at its advantages, uses, and step-by-step installation procedure.

Understanding Cold Shrink Cable Joints

Heat shrinkable cable termination is a method used to seal, insulate, and protect the connection between electrical cables. It involves using specially created materials that, when heated, shrink to form a tight seal around the cable termination, producing a strong, watertight, and long-lasting joint.

Benefits of Heat Shrinkable Cable Termination

Enhanced Insulation: Heat shrinkable materials have excellent insulation qualities, which lower the possibility of electrical leakage and guarantee peak performance.

Mechanical Strength: The tightly sealed termination provides mechanical support, safeguarding the cable joint from stresses, vibrations, and environmental factors.

Environmental Protection:The sealed termination is resistant to moisture, chemicals, and other harsh environmental conditions, prolonging the lifespan of the connection.

Reduced Risk of Corrosion: By creating a barrier against moisture and contaminants, heat shrinkable terminations help prevent corrosion, which can degrade the performance of cables over time.

Applications of Heat Shrinkable Cable Termination

Power Distribution Networks: Heat shrinkable terminations are commonly used in power distribution systems to connect high-voltage cables and ensure reliable electricity transmission.

Industrial Applications: Industries rely on heat shrinkable cable terminations to maintain safe and efficient operations in harsh environments such as factories, refineries, and processing plants.

Telecommunications: This technique is utilized in the installation and maintenance of telecommunication networks, ensuring seamless connectivity and data transmission.

Renewable Energy: Heat shrinkable cable terminations play a crucial role in renewable energy projects, connecting cables in solar panels, wind turbines, and other green energy systems.

Installing Heat Shrinkable Cable Terminations: Step-by-Step Guide

1. Gather Necessary Tools and Materials:

Heat shrinkable termination kit

Heat gun or torch

Cable preparation tools (strippers, cutters, etc.)

Cleaning materials (alcohol wipes, brushes, etc.)

2. Prepare the Cable Ends:

Strip the cable ends to expose the conductors.

Clean the exposed conductors thoroughly to remove any dirt, grease, or oxidation.

3. Select and Position the Heat Shrink Tubing:

Choose the appropriate size of heat shrink tubing to fit snugly over the cable termination.

Slide the tubing onto the cable, ensuring it covers the entire termination area.

4. Apply Heat:

Using a heat gun or torch, evenly apply heat to the heat shrink tubing.

The tubing will shrink and form a tight seal around the cable termination.

5. Inspect and Test the Termination:

Ensure that the tubing has fully shrunk and formed a secure seal.

Conduct a continuity test to verify the integrity of the connection.

Conclusion

For any electrical engineer or technician, mastering the art of heat shrink cable termination is a valuable skill. This method is essential for preserving dependable electrical connections across various industries thanks to its many advantages and broad applications. You can confidently use this method in your projects to ensure long-lasting and secure cable terminations by carefully following the provided installation guide.

Kindly provide your information, and our expert team will get in touch with you shortly.